Traceability Systems

We enhance transparency in automobile production. Track, trace, and optimize every step from start to finish.

Traceability Systems for Automobile Production

At Paveway Automation, we enhance transparency, quality, and efficiency in every phase of automotive manufacturing. Our system allows precise tracking and tracing of components, ensuring compliance, reducing risks, and enabling data-driven decisions.

Key Areas of Waste Elimination

End-to-End Traceability

Track every component and process throughout the production cycle. Ensures complete oversight and quality assurance.

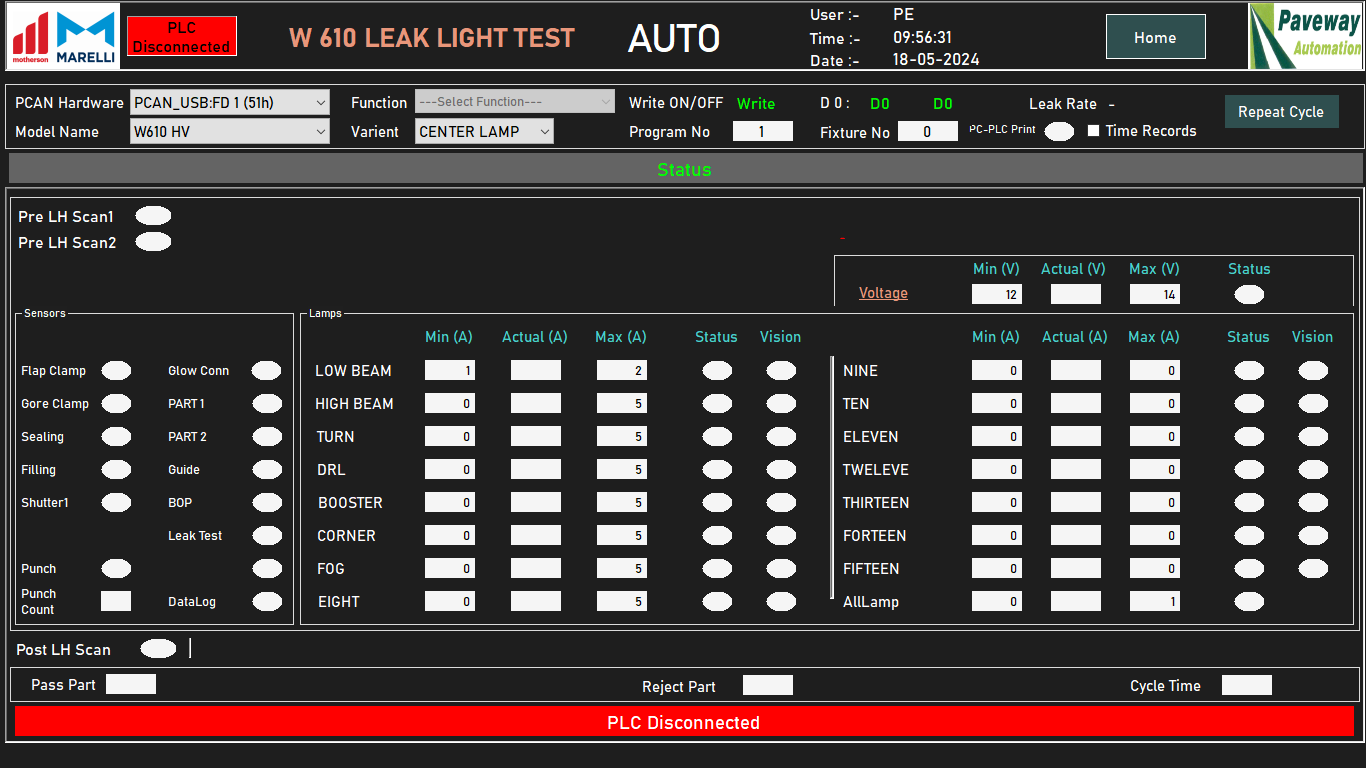

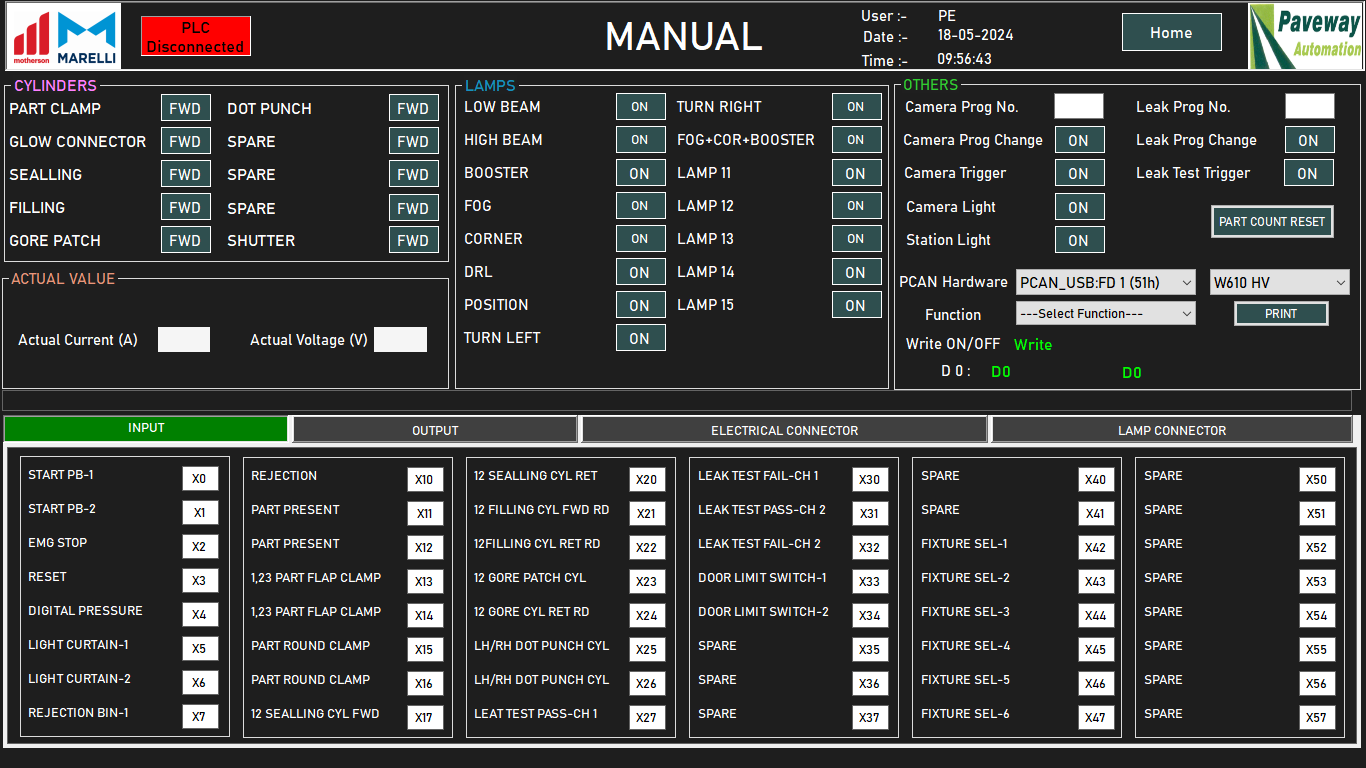

Real-Time Data Collection

Capture live data from machines, sensors, and production lines. Enables quick decision-making and reduces downtime.

Quality Control and Compliance

Monitor quality at each stage to meet industry standards. Minimizes defects and enhances customer satisfaction.

Process Optimization

Identify bottlenecks and inefficiencies with advanced analytics. Improves productivity and reduces operational costs.

Automated Documentation

Create detailed logs and reports automatically. Facilitates easy audits and regulatory compliance.

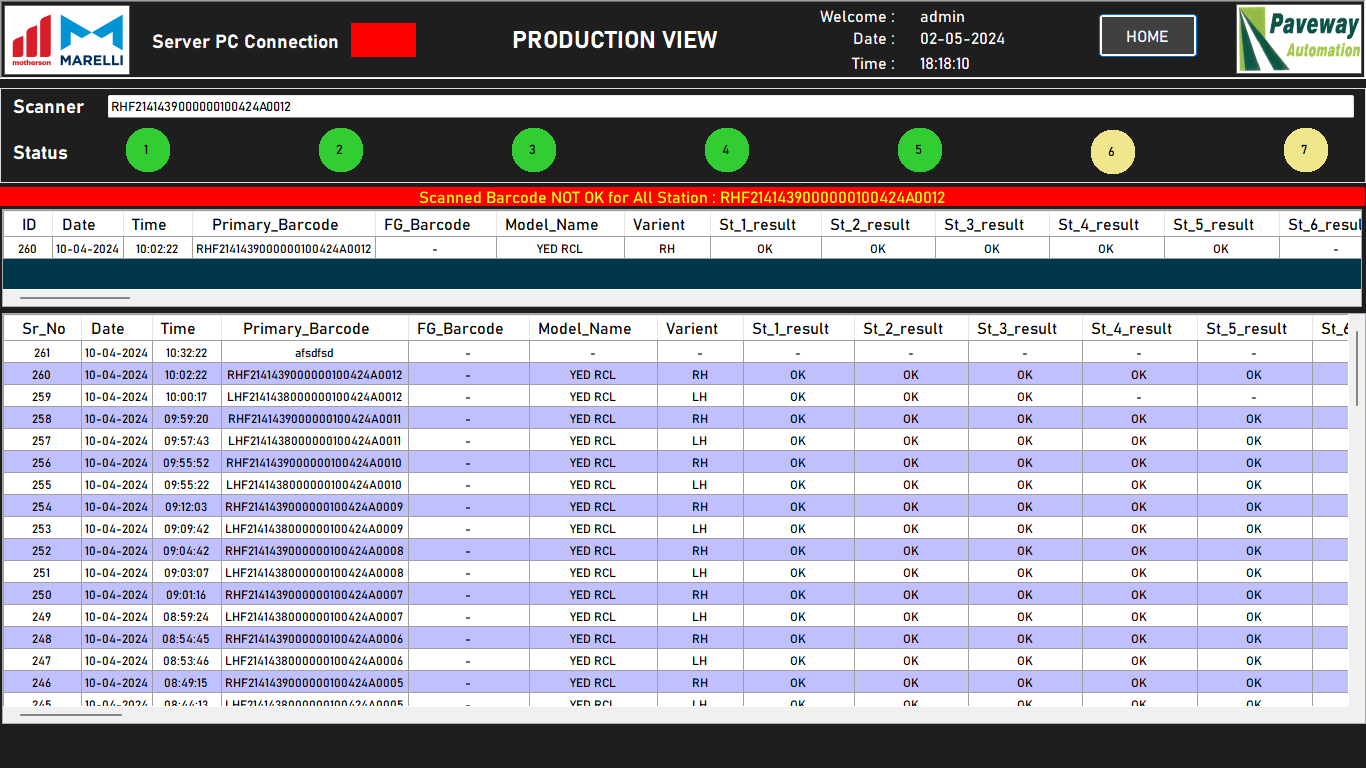

Defect Detection and Recall Management

Rapidly trace faulty parts back to their source. Simplifies recall management and minimizes impact.

Benefits of Paveway’s Traceability Systems

Boosted Product Quality

Reduced defect rates by identifying issues early in production.

Improved Production Efficiency

Increased uptime and optimized workflows through predictive maintenance and real-time data.

Enhanced Transparency and Accountability

Increased consumer trust with verifiable quality and safety standards.

Reduced Operational Costs

Lower recall expenses, reduced material waste, and optimized resource usage.

How Our Traceability System Works

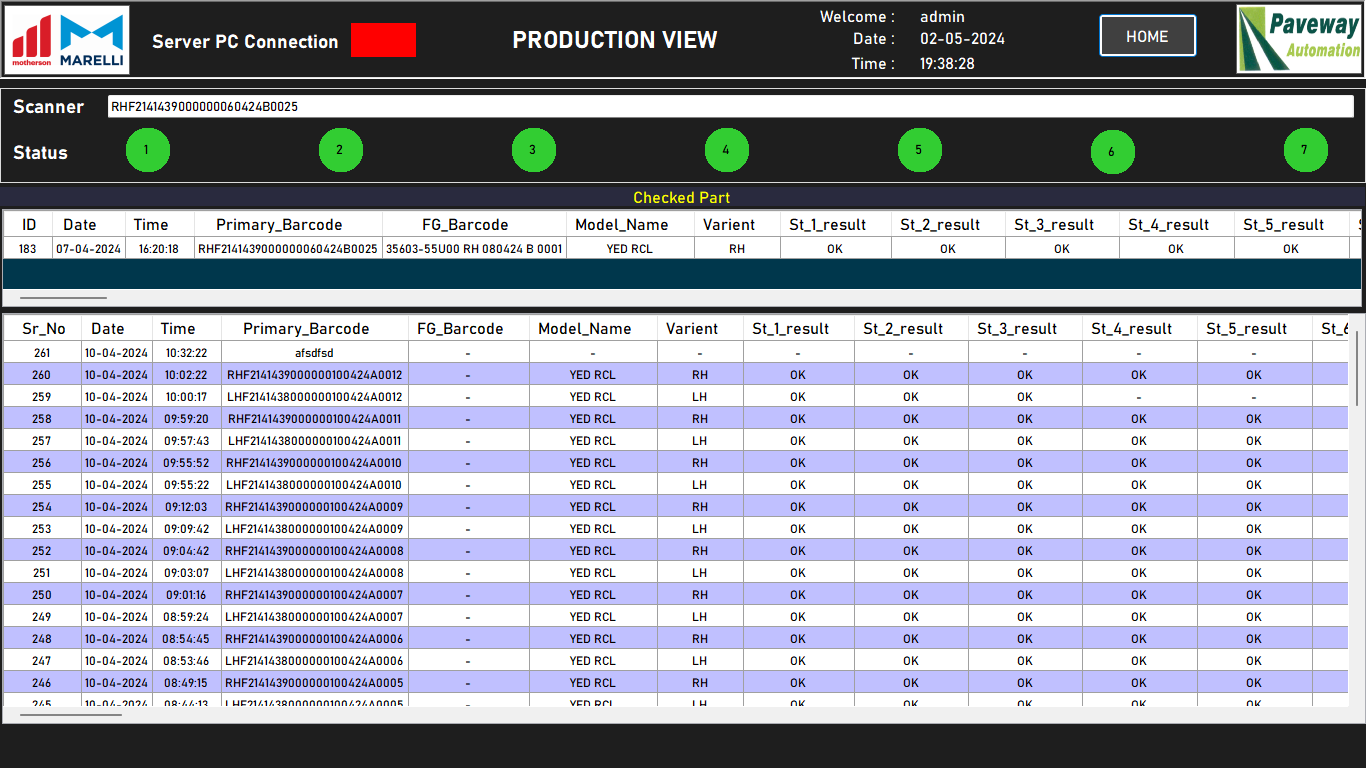

Our traceability system uses unique IDs like barcodes and RFID to track each item, providing real-time visibility and a permanent production record.

Track Components

from suppliers to final products, ensuring complete production transparency.

Analyze Production Data

to detect patterns, prevent defects, and improve operational efficiency.

Generate Compliance Reports

automatically, making regulatory reporting simple and error-free.

Isolate Defective Products

for faster, more accurate recall processes, safeguarding consumers and protecting the brand.

Comprehensive Traceability Solutions

Our traceability systems can integrate additional capabilities to enhance transparency and accountability across the production lifecycle

Supplier Quality Management

Tracks and records data from suppliers, linking component quality to specific suppliers and batches, which aids in root-cause analysis and quality improvement.

Lifecycle Management

Manages component histories, enabling full product lifecycle traceability, beneficial for industries with long-term regulatory obligations, such as aerospace and medical devices.

Serialized Component Tracking

Allows each individual product or part to be uniquely identified, essential for batch recalls and historical record-keeping in highly regulated sectors.

Environmental Monitoring

Records environmental factors (temperature, humidity, etc.) during production, ensuring compliance with conditions for sensitive products, like pharmaceuticals.

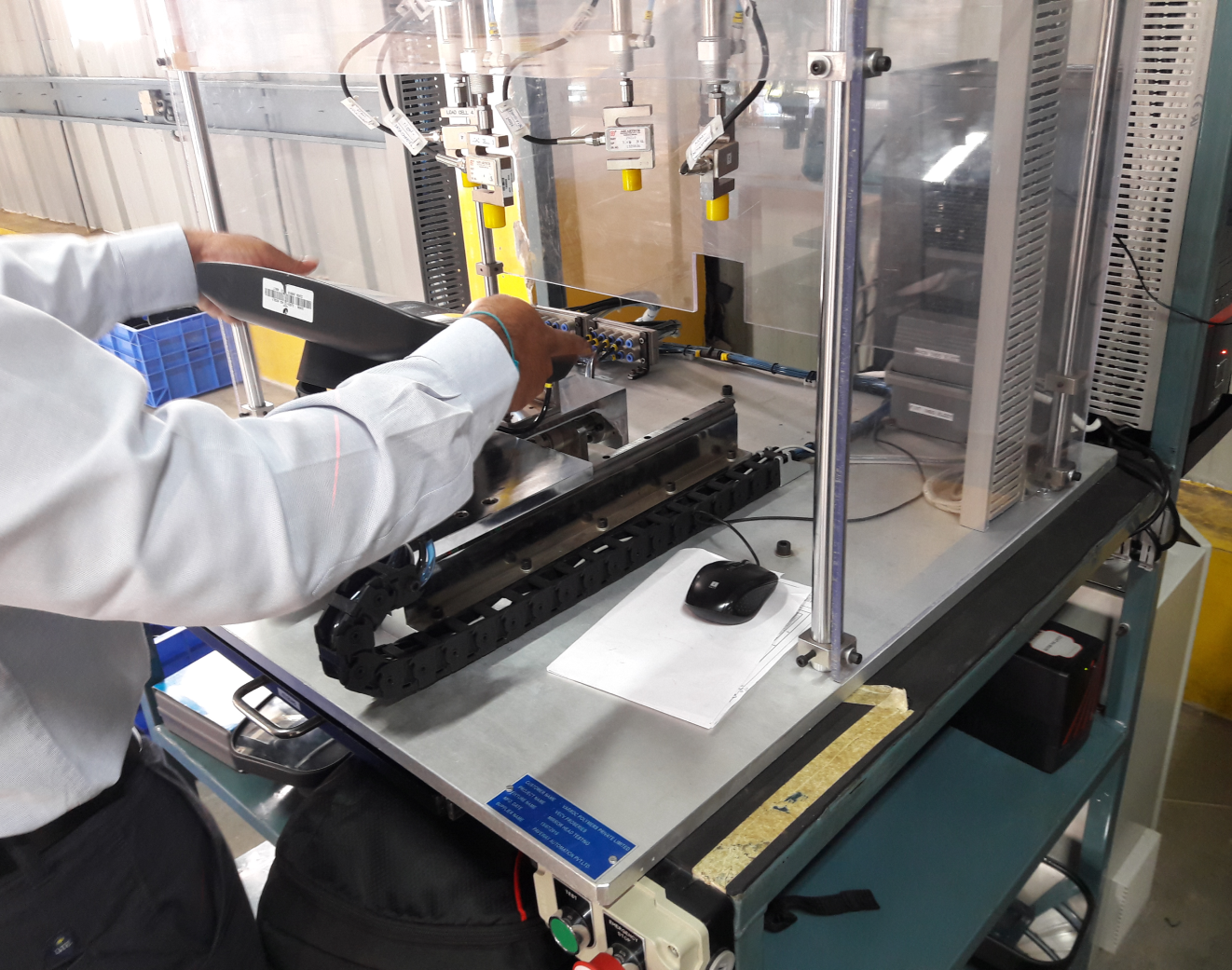

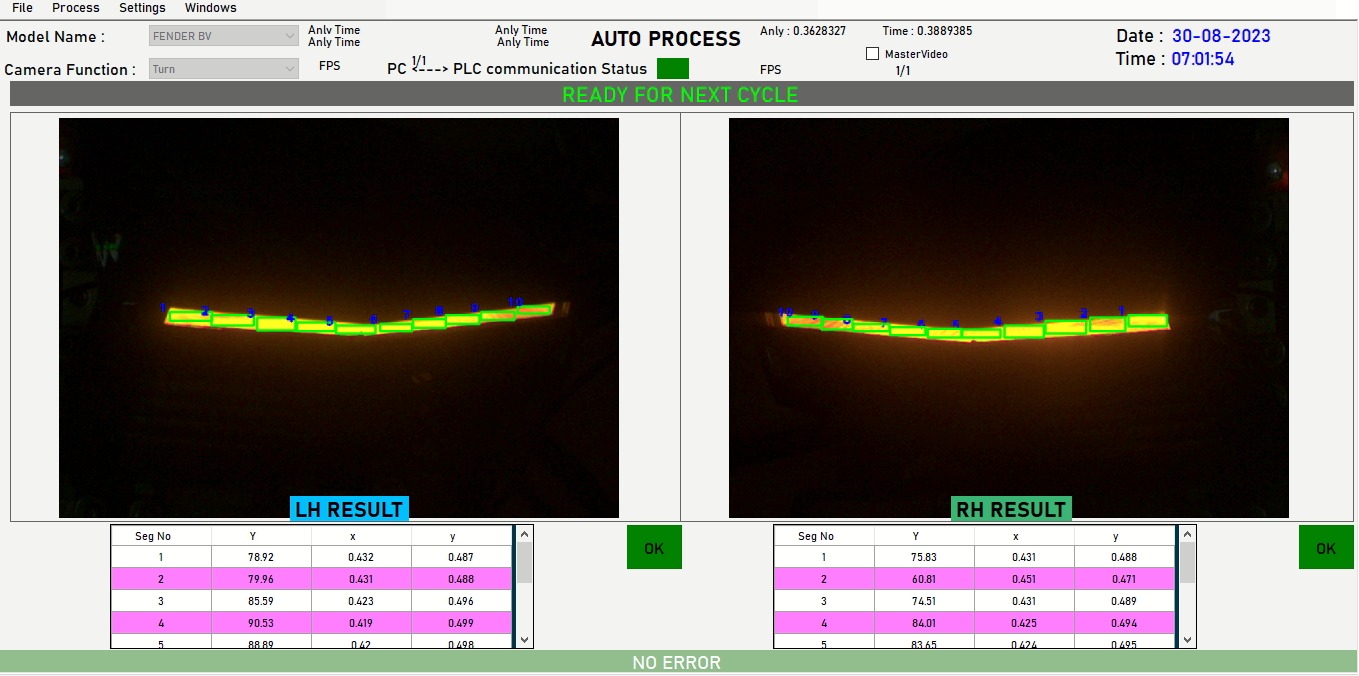

Automated Vision Inspection for Modern Manufacturing

Vision-Based Systems

As production demands grow, Paveway Automation’s vision-based inspection systems provide fast, accurate quality checks to keep pace with high-speed manufacturing.

Key Areas of Inspection Capabilities

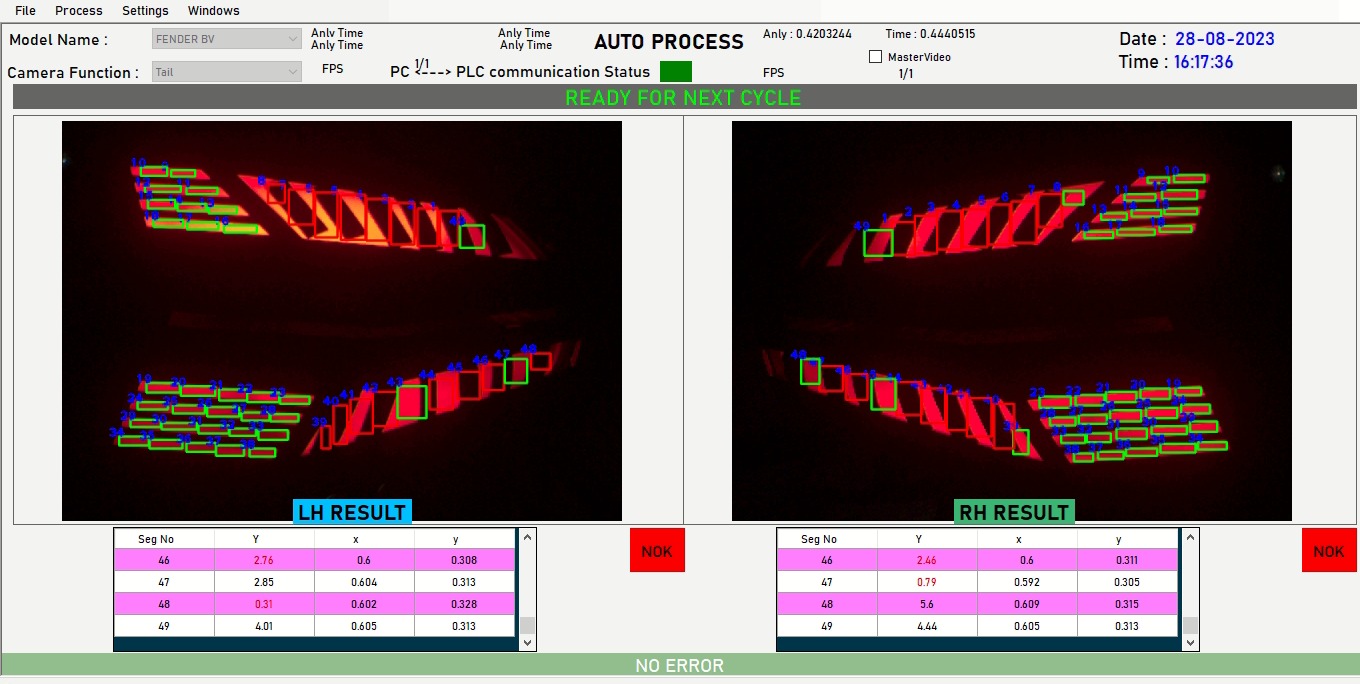

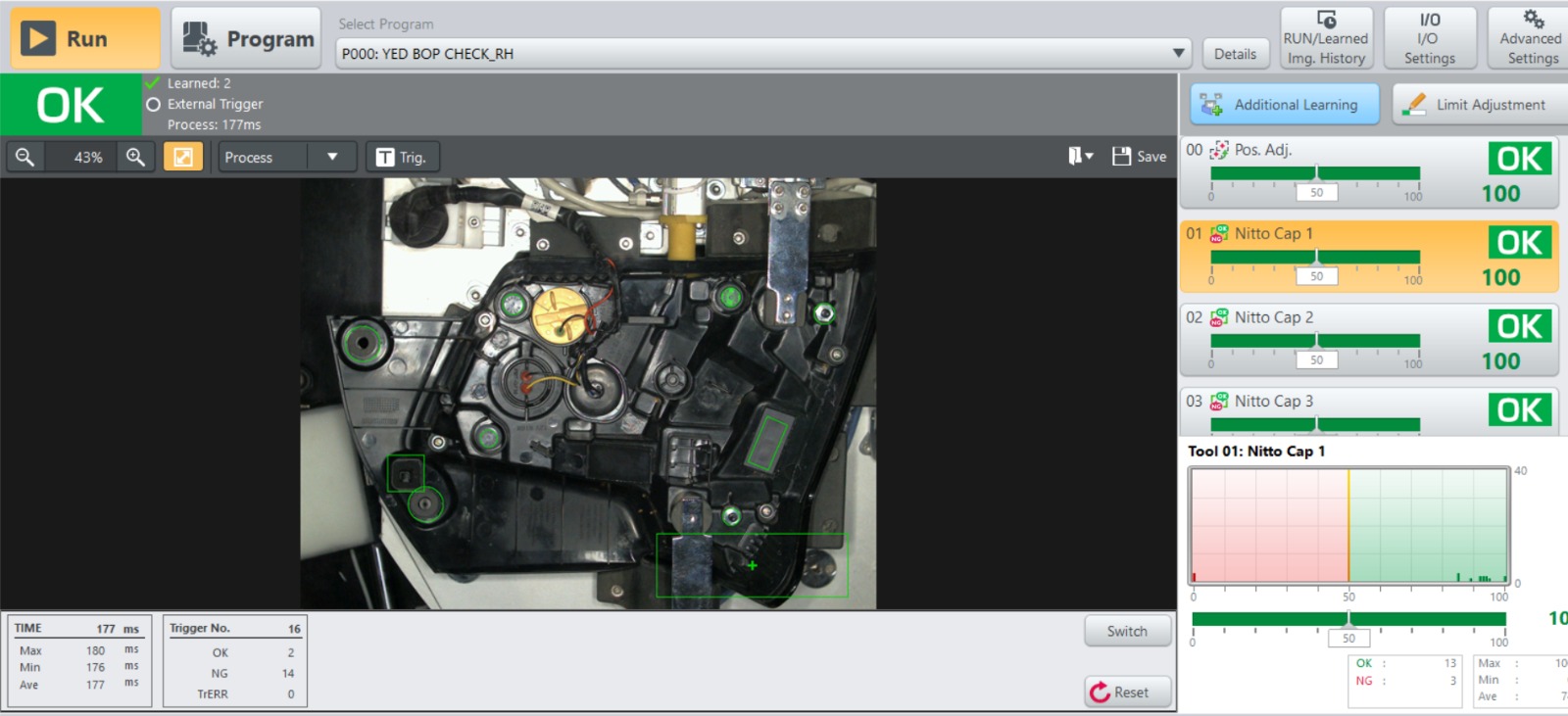

Pattern Matching

Identifies and verifies specific patterns to ensure correct assembly or packaging.

Object Counting

Accurately counts items moving through the production line, ensuring inventory accuracy and production tracking.

Optical Character Recognition (OCR)

Reads printed or engraved characters on products for real-time verification of serial numbers or text-based quality checks.

Bar-Code Reading

Scans barcodes for product identification, batch tracking, and ensuring compliance with regulatory standards.

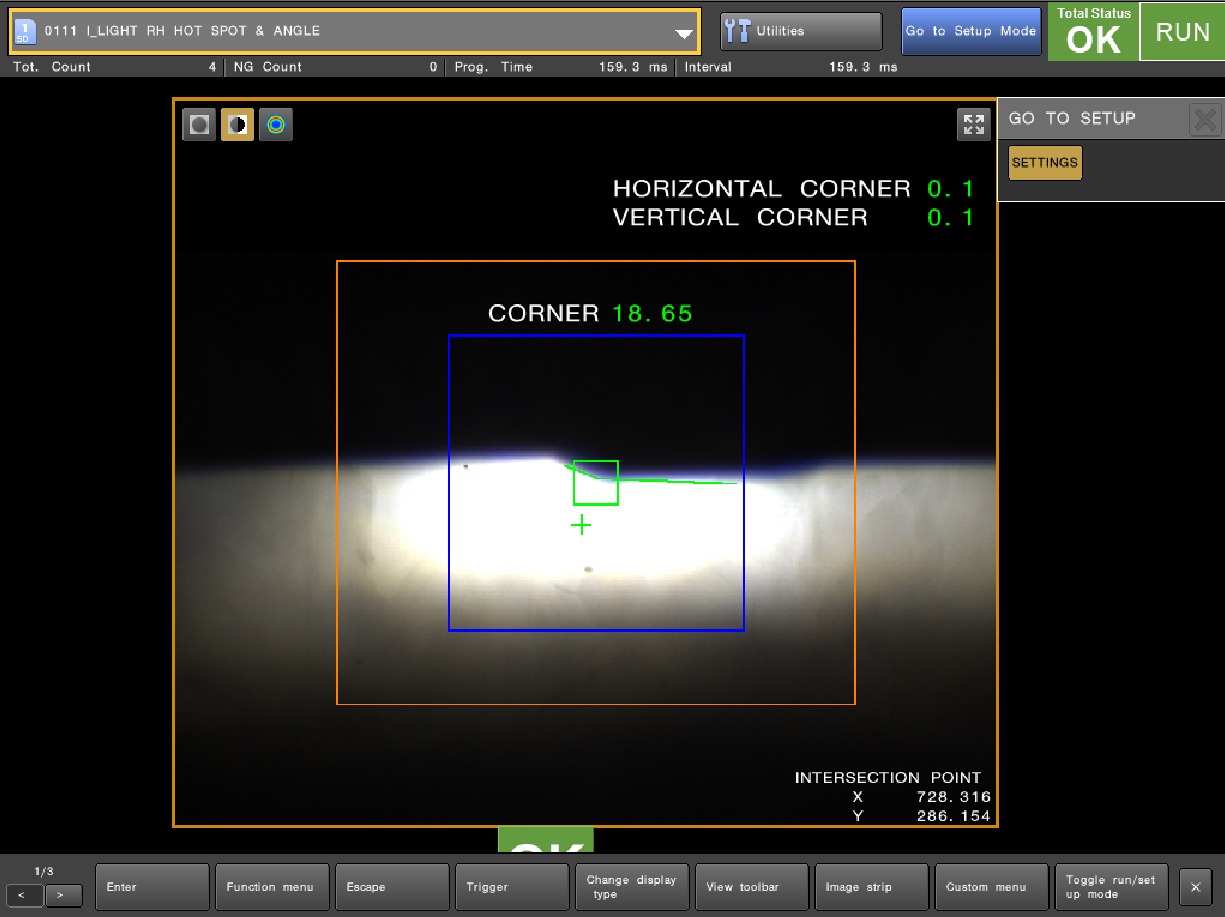

Dimensional Measurement

Measures object dimensions to ensure they meet precise specifications, ensuring consistency and reducing defects.

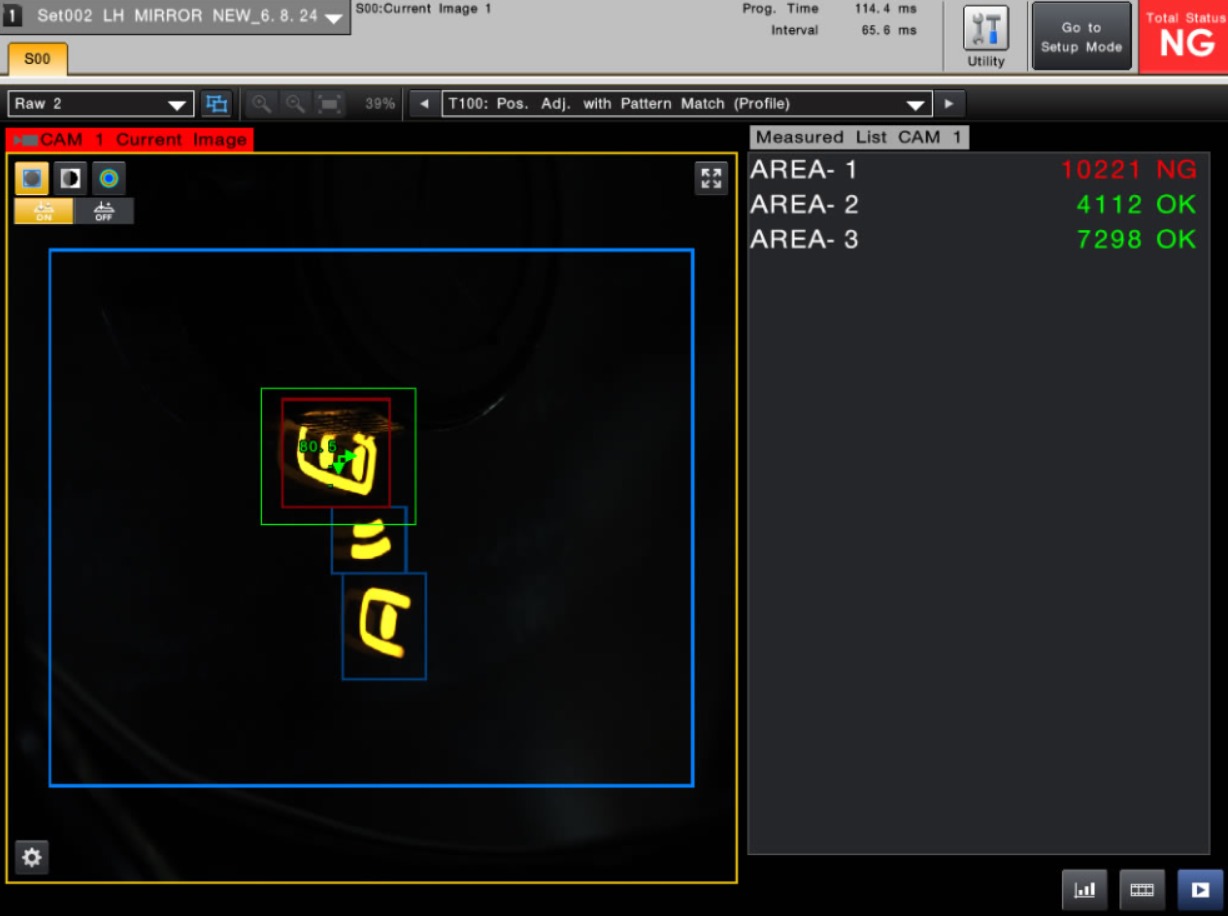

Defect Detection

Automatically identifies surface defects, missing components, or irregularities, ensuring only high-quality products move forward in the production process.

Collaborative Partnerships for Superior Solutions

Our close partnerships with leading vision camera manufacturers, combined with our in-house expertise in designing and developing automated systems, allow us to deliver reliable and fully integrated vision-based inspection solutions. These systems not only enhance quality control but also increase overall production efficiency.

Value-Driven Benefits of Paveway’s Vision Systems

Seamless Integration

Our vision systems can be integrated directly into your existing production lines, with minimal disruption and maximum impact.

High-Speed Inspection

Designed to keep up with today’s fast-paced production environments, our systems perform real-time inspections without slowing down your operations.

Improved Accuracy

Advanced algorithms ensure highly precise inspections, reducing errors and improving overall product quality.

Your Automation Expert

Achieve more with our innovative automation solutions. Let’s enhance efficiency and drive your business forward!