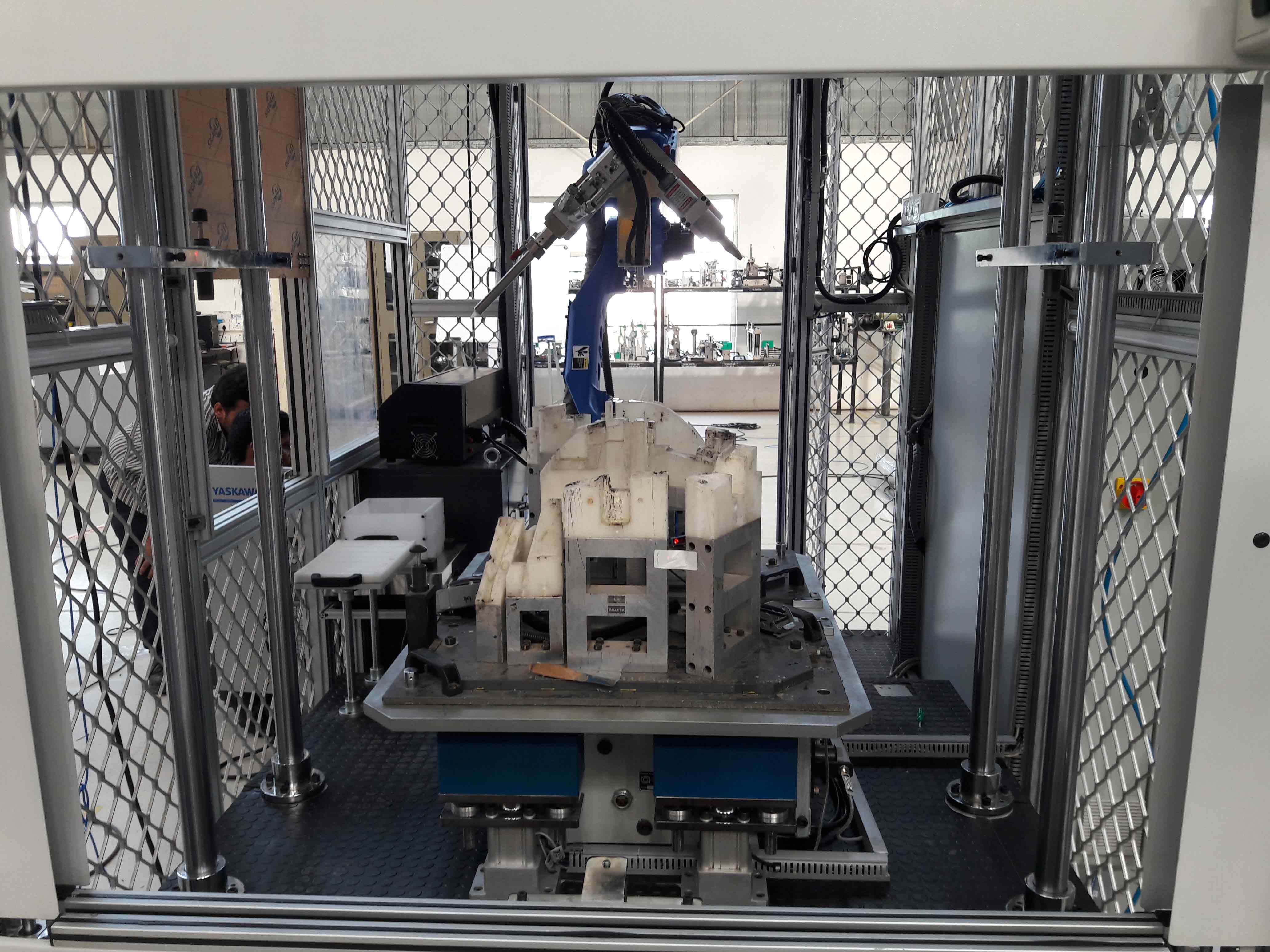

Special Purpose Machines

SPMs boost accuracy and efficiency in car manufacturing, integrating robotics and AI for faster production and quick ROI.

Advanced Testing Solutions for All Industries Using Special Purpose Machines

At Paveway Automation, we specialize in designing and developing advanced test rigs tailored for a wide range of industrial applications. Our testing solutions are built to ensure precision, durability, and performance across different sectors.

End-of-Line (EOL) Performance Testing

Ensures product functionality and quality before it leaves the production line.

Endurance/Durability Testing

Verifies that products can withstand long-term usage and harsh conditions.

Functional Testing

Confirms that each component operates correctly and meets required specifications.

Enhanced Test Rig Features

Single-Minute Changeover Fixtures

Enables quick changes in setup, minimizing downtime between tests.

Automated Transfer and Handling

Integrates with automated systems for smooth and efficient part movement during testing.

Vision Systems Integration

Incorporates visual inspection technology to ensure precise testing results.

Standard Testing Equipment

Our systems are compatible with industry-standard equipment, ensuring reliable and accurate testing outcomes.

Optimized Test Rig Design

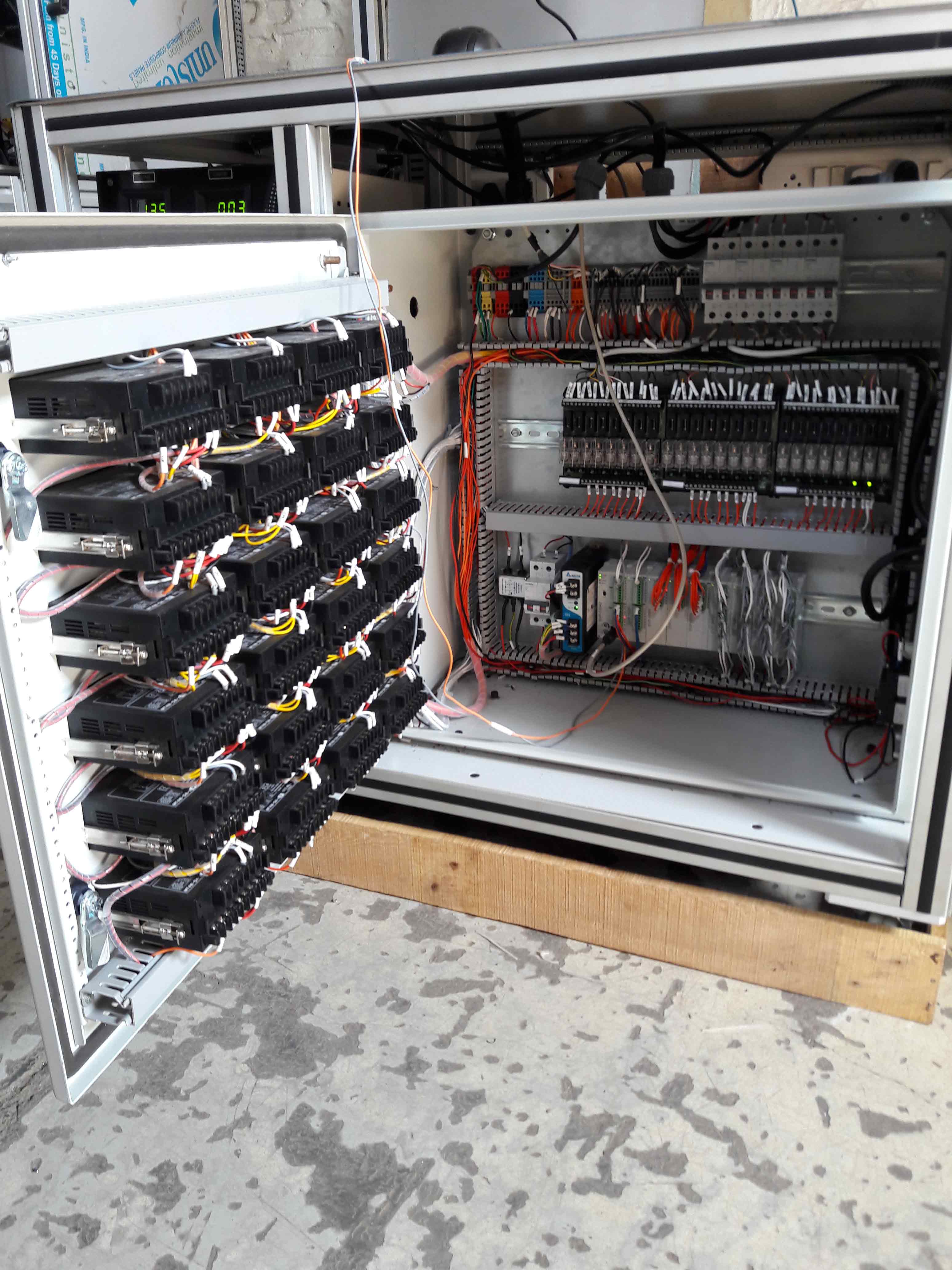

Custom Interfaces

We integrate mechanical and electronic components, including power supplies, electrical connections, and traceability systems to meet specific testing requirements.

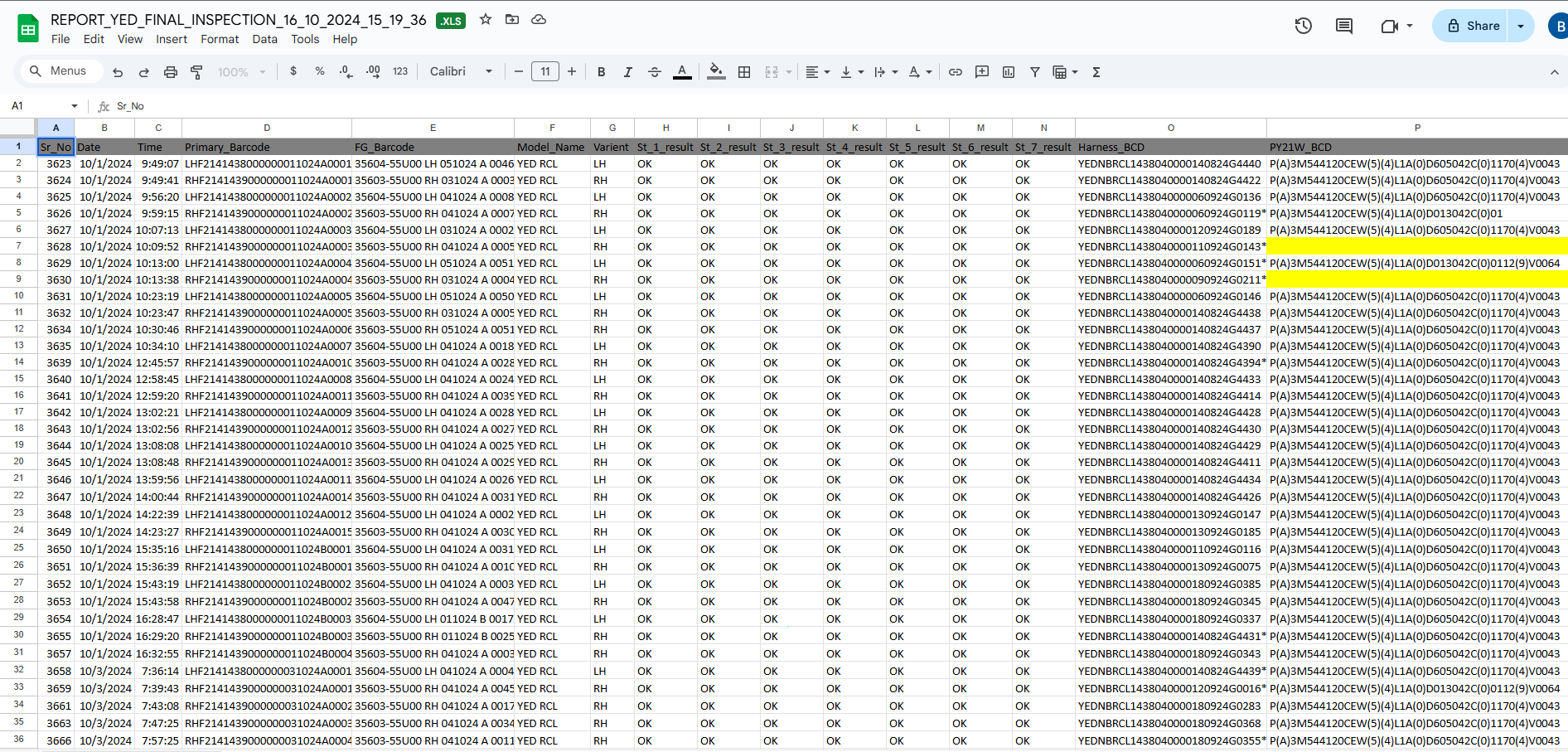

Data-Driven Insights

Our systems collect valuable testing and calibration data, enabling detailed performance analysis and fault detection, which ultimately boosts product yield.

User-Centric Controls and Automation

The rigs are equipped with automated test sequences and user-friendly controls, enabling operators to conduct tests with precision and efficiency. This reduces operator training time and ensures consistent testing outcomes.

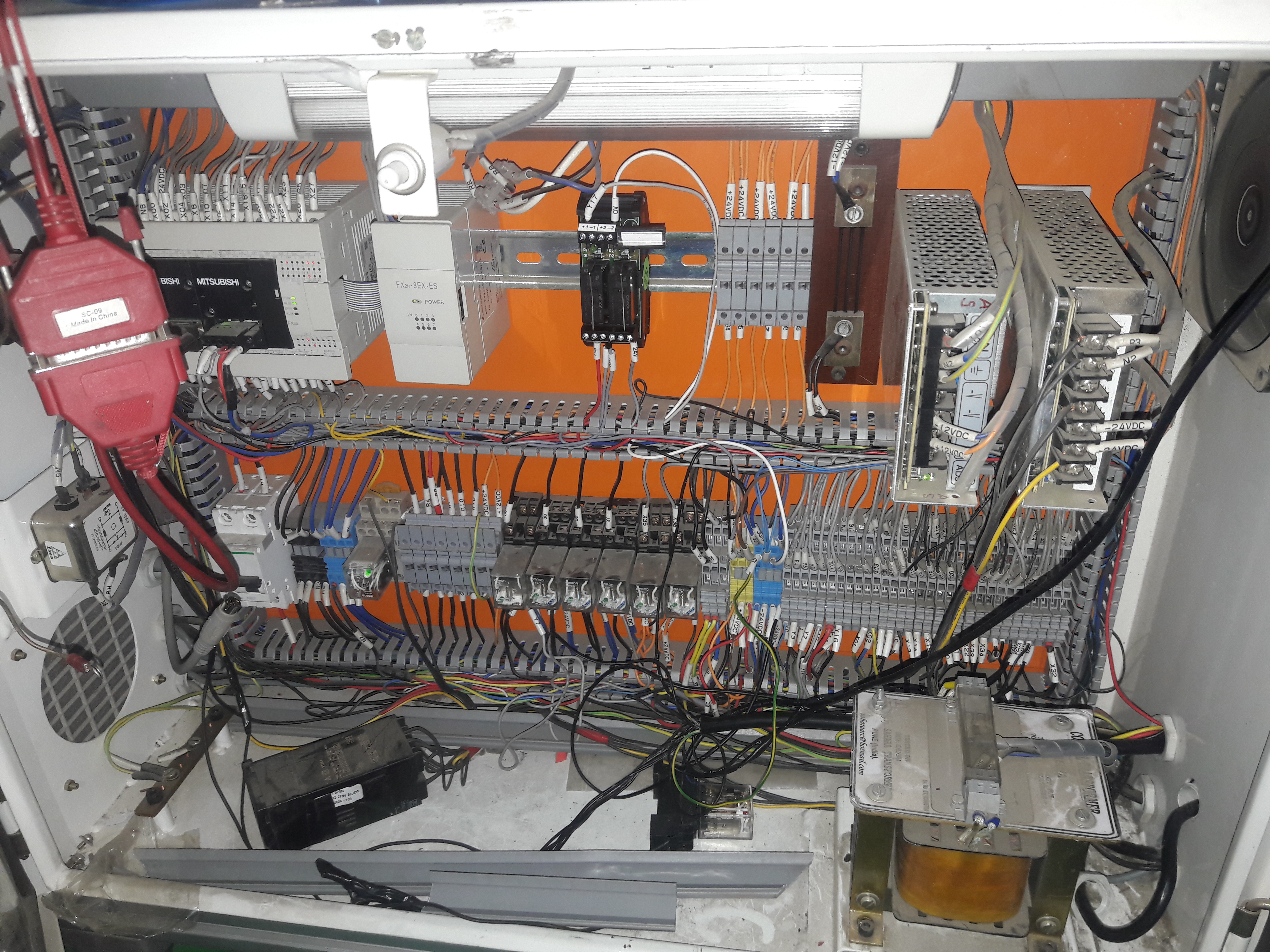

Control Panels for Special Purpose Machines

Our control panels for SPMs are designed to provide intuitive, precise, and reliable machine control, ensuring that specialized production tasks are carried out efficiently and consistently.

Key Features of SPM Control Panels

User-Friendly Interface

Simplifies machine operation with intuitive, touchscreen HMIs (Human-Machine Interfaces) that allow easy monitoring and adjustment of parameters.

Customizable Controls

Tailored control configurations to meet specific task requirements, such as automated sequencing, precise timing, and synchronized multi-axis control.

Advanced Diagnostics

Includes built-in diagnostics and alert systems to detect faults and assist operators in troubleshooting, minimizing downtime.

Real-Time Data Monitoring

Enables operators to track production data, machine status, and key metrics in real time, enhancing decision-making and efficiency.

Safety and Compliance

Equipped with emergency stop functions, lockout mechanisms, and other safety features to ensure operator safety and meet industry regulations.

Integration with PLCs and SCADA Systems

Seamlessly integrates with PLCs and SCADA systems for centralized control and data analysis in complex production setups.